Picking the best roofing for industrial buildings brings special difficulties. Materials must handle tough conditions. They also need to give lasting worth. The roof has to shield operations from bad weather. It should aid in managing inside temperatures. Plus, it must fit rising green rules without losing strength.

Industrial roofs deal with harder tasks than those in shops or homes. They span bigger spaces. They often hold heavy gear. The materials resist chemical harm, strong winds, and heat shifts. Yet, they help cut power bills. They need little upkeep over the years.

Firms such as Jieli have made focused fixes for these tricky issues. Their roofing setups mix modern materials with useful design parts. These items are built just for industrial uses where trust counts a lot. They provide the toughness and heat control that today’s sites demand. They back green aims too.

When you plan roofing for industrial buildings in 2025, you probably focus on how well it works, saving money, and following rules. The best roofing fix must last in rough spots. It has to take ongoing work stress. Strength against weather like sun rays, damp air, and chemical wear is a must. Many industrial spots hold work or goods that react to heat changes. So, heat blocking is key.

Besides fighting weather, the roof must bear machine weight. This could be steps for fixes or big roof gear. Lasting a long time matters too. Roofs are big buys. They should cut total costs by cutting fixes and swaps. Heat saving leads to power cuts. This grows important as firms push for cleaner work.

Fitting new green orders and safety steps changes how you pick roofing stuff. Industrial setups in 2025 must match power-saving rules. They lean toward fixes that hit fire-safe levels like B1 or Class A marks.

UPVC roof sheet is hard to burn. It puts out fire on its own. The fire rating is B1. Green goals shape company plans and state rules. Your roofing picks now sway if your building gets green badges. That is why safe, reusable stuff with less harm to nature sets the norm.

For industrial jobs in harsh spots or wild heat changes, UPVC roofing stands out. PVC roof sheet/UPVC roof sheet, ASA UPVC roof sheet and ASA synthetic resin roof tile, main material are PVC. This kind of material’s characteristics are Heat and Sound insulation, Rust free and Chemical corrosion resistance. These traits help a lot in fields like chemical work, cloth making, and food prep.

The small heat pass rate—about 0.325 W/m.k—gives blocking power better than metal picks. The thermal conductivity of PVC material is 0.325w/m.k. This is about 1/2000 of color steel sheet. Also, UPVC sheets keep color steady under sun rays. This comes from the ASA coat layer. It holds color for up to 10 years.

Next to metal or asbestos picks, UPVC lasts longer. This holds true in spots where harm eats away. Steel might rust or break fast there. It is very good alternative for pre-painted color steel sheet (color steel sheet is easy to rust, transfer the heat very fast and very noisy when rain and wind).

Upkeep needs are small. This is due to its safe-from-harm face. One plus that folks miss is sound ease. UPVC cuts rain sound a lot. UPVC roof sheet is sound insulation. It can reduce 25~30 Db. So it is not noisy when raining. It is not like steel sheet.

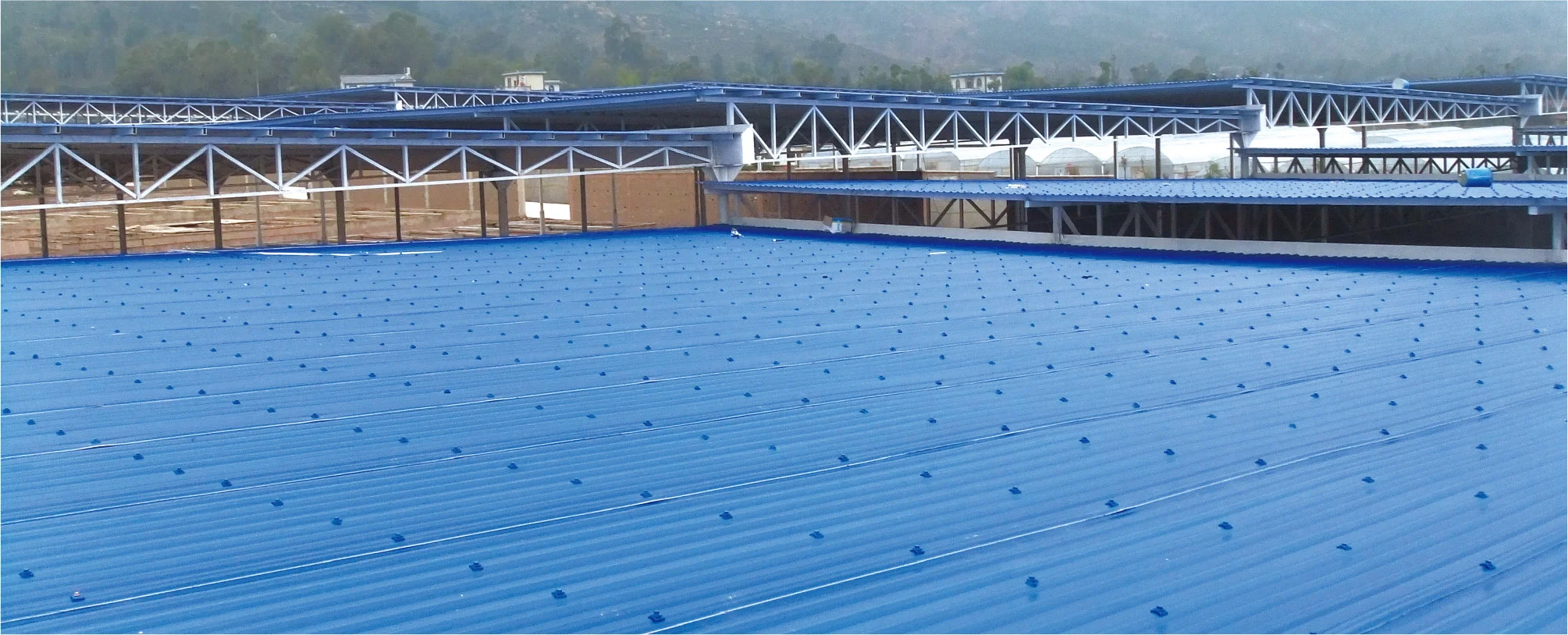

The T1130 UPVC Roofing Sheet is made for tough industrial jobs. Its three-part joined structure blends power, blocking, and sun fight in one piece. The full width is 1130mm. The useful cover fits big setups well. It suits plants with wide roofs.

Fiber glass reinforced UPVC roof sheet is our Patent tech product. We add one layer of Fiber glass mesh inside PVC/UPVC sheet. This inside glass boost raises pull strength and weight hold. It matters in spots where big gear sits on the roof.

This type shines in plants with chemical touch or high damp. Think cloth mills or chemical units. Its top blocking cuts the need for extra coats. This helps storage spots that need heat rule. They want to skip added build weight.

Its strength against wild weather cuts shape loss over time. The shiny top layer helps keep inside cool in hot times. This means lower cool costs. It aids work that eyes power saving.

The T1088 UPVC Roofing Sheet gives a fair mix of power and bend for medium roof jobs. The width is 1088mm. The thick spread is set right. It holds hit force well. It skips extra weight or price.

This type fits mid-size shipping hubs or storage spots. There, mild weather touch needs strong stuff. But it does not call for too much build.

It works in shops, storage buildings, and half-open setups. This fits areas with rain seasons or heat swings. The T1088 gives enough blocking. It skips the heft of more stuff.

Quick setup is a big help. Its size makes it easy to move. This cuts work costs and stop time. It fits standard steel frame systems in industrial builds.

If your job has roof adds like sun power boards or air units, the T1130’s stiff build gives the hold needed for safe long life. The T1088, on the other hand, brings easy grip and setup. It still gives strong work for most industrial needs.

Both types use low heat pass to trim inside heat rise. Yet, the T1130’s three-part build gives it a lead in heat block. It suits spots with wild heat or tight weather hold in your site.

To make the full setup work, add-ons like ridge tops, end tops, and weather-safe glues come in same stuff and shades. The accessories products include Ridge cover, three way, side ridge, eave, cladding, flashing…

Hold-downs have rust-fight traits. They bond tight with UPVC pieces over time.

Right setup brings long life. Suggested slant angles help water flow well. Purlin space should stay under 1200mm for best weight spread. Purlin distance: <1200mm

Setup looks like that of old steel pieces. But it gains from light weight and simple hold.

Before you pick your roofing maker, think of a team that joins new ideas with strict check control. Started in 1992, Jieli has become a top maker in China. It focuses on fresh roofing tech. This includes UPVC sheets with glass mesh boost and many-layer joined ways.

Jieli has own Testing lab. This lab is also authorized by Government as the testing center of UPVC roofing products. Each batch goes through hard checks. These cover age tests, pull strength, hit hold. They make sure steady item work.

Custom work includes set thicks (1.5mm–3.0mm), shade match, and plan tweaks based on job needs. Tech pros help with CAD plans and count math for hard jobs. Our technical engineer can help to work out the project drawing, and calculate the using quantity.

Their world list covers big build jobs in South America and Asia since 2012. Jieli stands by its promise to deliver top-notch products that meet the real needs of industrial users. Their team offers quick support, from initial talks to after-sale care. This builds trust with clients around the globe. With years of hands-on know-how, Jieli keeps pushing limits in roofing tech. They focus on making items that not only last but also save money in the long run. Clients value the clear talk and pro advice that Jieli provides at every step.

Q: How long does the color on UPVC roofing last in outdoor industrial environments?

A: The ASA surface layer offers UV protection that keeps colors stable for 8–10 years even under prolonged sun exposure.

Q: Are UPVC roofing sheets suitable for high-humidity environments?

A: Yes. Their chemical corrosion resistance makes them ideal for settings like food factories or coastal warehouses where moisture levels are consistently high.

Q: Can these roofing sheets be walked on during maintenance?

A: The reinforced structure—especially in models like T1130—supports maintenance access when installed with correct purlin spacing and slope angles.